Running a successful business involves more than just making investments; it’s about smart financial decisions that keep operational costs in check. One area where businesses can significantly optimize their expenses is in reducing food packaging costs. Many entrepreneurs, however, may be unaware of the factors influencing packaging prices and how to leverage them to their advantage. In this blog, we’ll explore the key factors affecting food packaging costs and provide 11 effective strategies to help you save thousands of dollars.

Unpacking the Factors: What Influences Food Packaging Costs?

Before delving into cost-cutting strategies, it’s crucial to understand the primary factors impacting food packaging costs. Recognizing these elements will lay the groundwork for making informed decisions.

1. Raw Material Costs

Ensuring that your packaging is both visually appealing and protective is essential. While investing in packaging is a powerful marketing tool, it doesn’t mean breaking the bank. Explore cost-effective alternatives and consider collaborating with manufacturers for reduced pricing on bulk orders.

2. Design and Customization

Achieving uniqueness in packaging is a common goal for businesses, but it can come at a cost. Design and customization may sometimes be expensive. Explore ways to minimize costs, such as using different inks for printing or finding more affordable customization partners.

3. Demand and Consumer Behavior

While you can’t control consumer behavior, you can influence it through innovative ideas. Experiment with different designs to educate consumers on options, potentially leading to reduced packaging costs.

4. Shipping and Handling

Shipping costs, damages during transportation, and product returns all contribute to the overall expense. Choosing the right materials is essential, but opting for the most expensive ones isn’t always the best solution. Explore alternative methods to minimize costs without compromising product safety with Food N Paks.

5. Sustainability and Environmental Factors

The shift towards eco-friendly materials is commendable, but it can be costly. For those less familiar with sustainable options, finding affordable yet better alternatives is key.

11 Strategies for Food Packaging Cost Reduction

Now, let’s explore actionable strategies to reduce food packaging costs without compromising on quality.

1. Embrace Eco-Friendly Materials Strategically

While initially more expensive, eco-friendly materials offer long-term cost benefits. Durable, reusable, and appealing to over 80% of consumers, they can enhance your brand’s trust and profitability.

2. Optimize Package Size

Customizable eco-friendly materials allow for efficient design changes. By reducing package size, you not only use fewer materials but also cut down on shipping costs by fitting more packages into a single shipment.

3. Diversify Packaging Materials

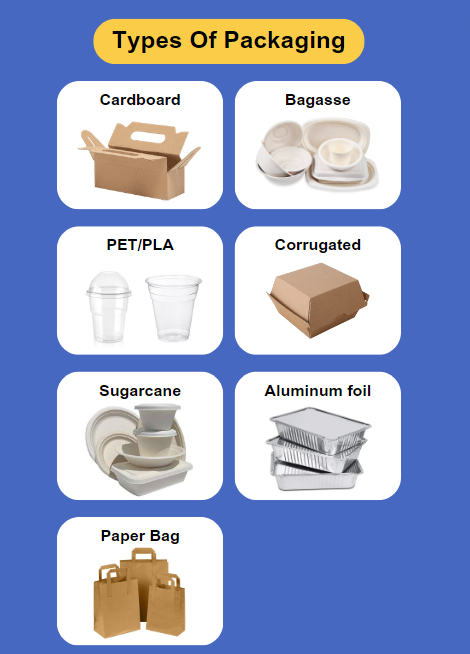

Experiment with different sustainable materials to find cost-effective options that resonate with your target audience. While cost reduction is crucial, enhancing product value can also improve profit margins.

If you find a sustainable alternative but the cost per package remains high, consider ordering larger quantities. Packaging manufacturers often offer lower prices for bulk orders.

5. Automate Packaging Processes

While initial investments may be required, automating the packaging process can lead to significant long-term cost reductions. It saves time, reduces errors, and lowers your carbon footprint.

6. Quality Control Before Shipping

Invest in pre-shipping quality control to identify areas for improvement in custom packaging. This reduces the chance of damaged products, minimizing returns and associated costs.

7. Stay Informed About Industry Innovations

Regularly analyze the market to stay abreast of industry innovations. Learn from competitors, adopt effective methods, and gain inspiration for your packaging designs.

8. Invest in Staff Training

Implementing automation and innovations won’t yield results without a well-trained staff. Invest time and resources in training your employees to ensure they contribute effectively to cost reduction.

9. Simplify Color Schemes

Avoid using too many colors in your packaging, as this can increase costs without necessarily enhancing the visual appeal. Streamlining color schemes can contribute to both aesthetics and cost savings.

10. Reduce Packaging Layers

Not every package requires three layers of protection. Evaluate whether a single layer can maintain product quality, speeding up production and reducing costs.

11. Collaborate with Packaging Experts like Food N Paks

Instead of navigating cost reduction efforts alone, consider partnering with specialized providers like Food N Paks. They offer eco-friendly custom packaging solutions and strive to provide competitive prices for larger quantities.

Final Thoughts: DIY or Collaborate?

Reducing food packaging costs can be approached in two ways. First, businesses can take the DIY route by implementing the tips provided in this blog. By finding cost-effective materials, automating processes, and making strategic decisions, they can achieve substantial savings.

The second option is collaboration with experts like Food N Paks. Their experience in branding and packaging, coupled with a focus on eco-friendly solutions, can not only cut packaging expenses but also enhance brand value and overall profitability.

Whether you choose the DIY approach or opt for collaboration, the key is to make informed decisions that align with your business goals. Start implementing these strategies today and watch your food packaging costs plummet while preserving quality and appeal.

(03) 8806 1672

(03) 8806 1672  sales@foodnpaks.com.au

sales@foodnpaks.com.au

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.